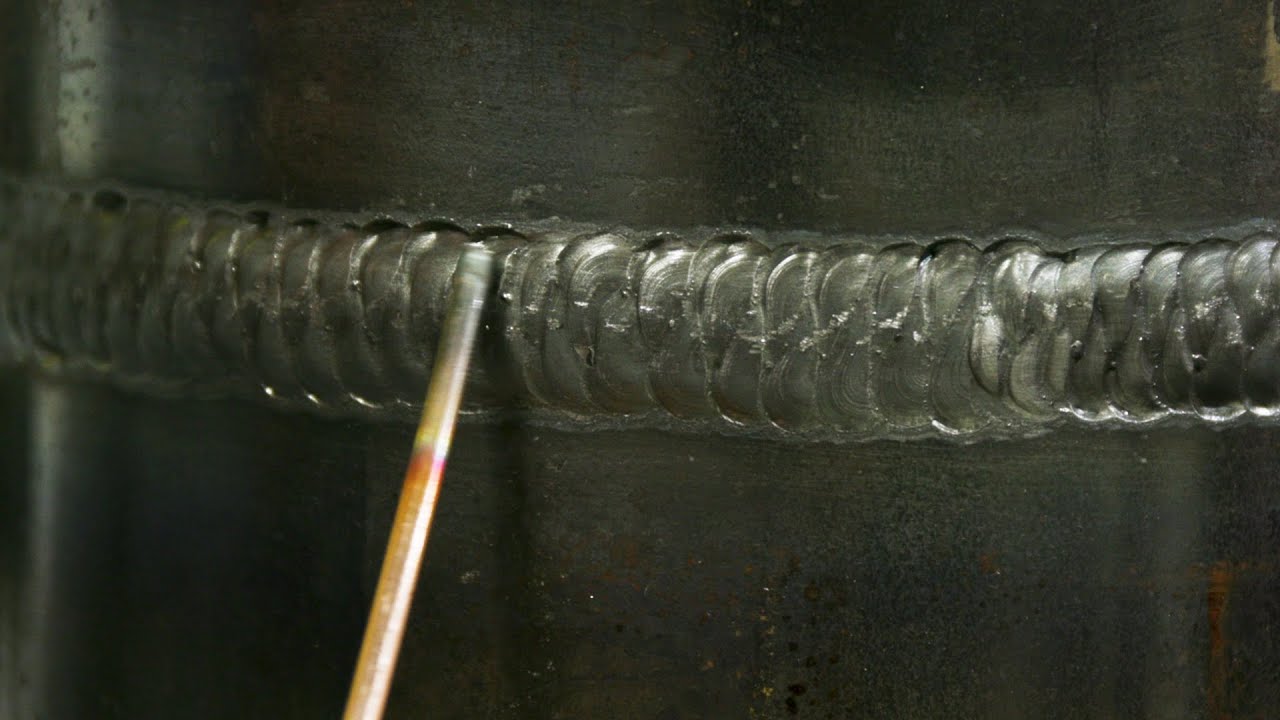

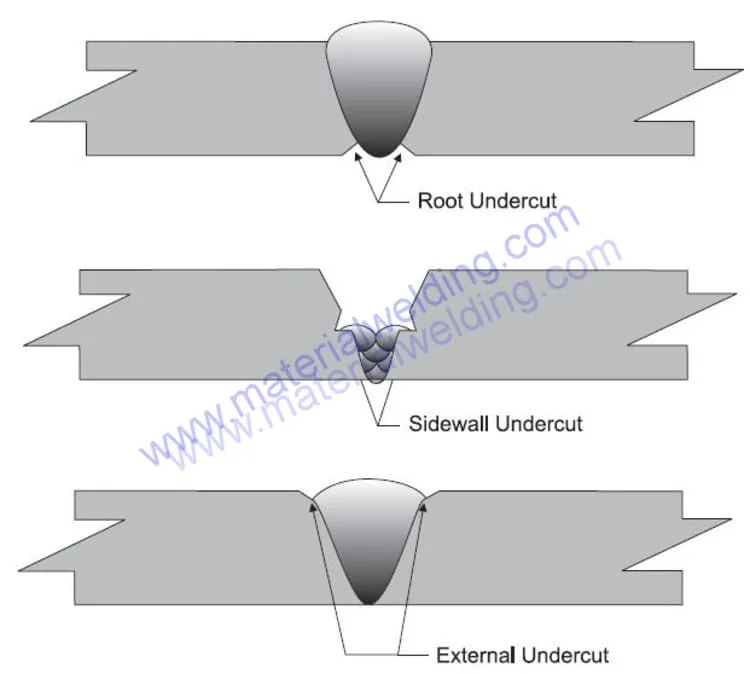

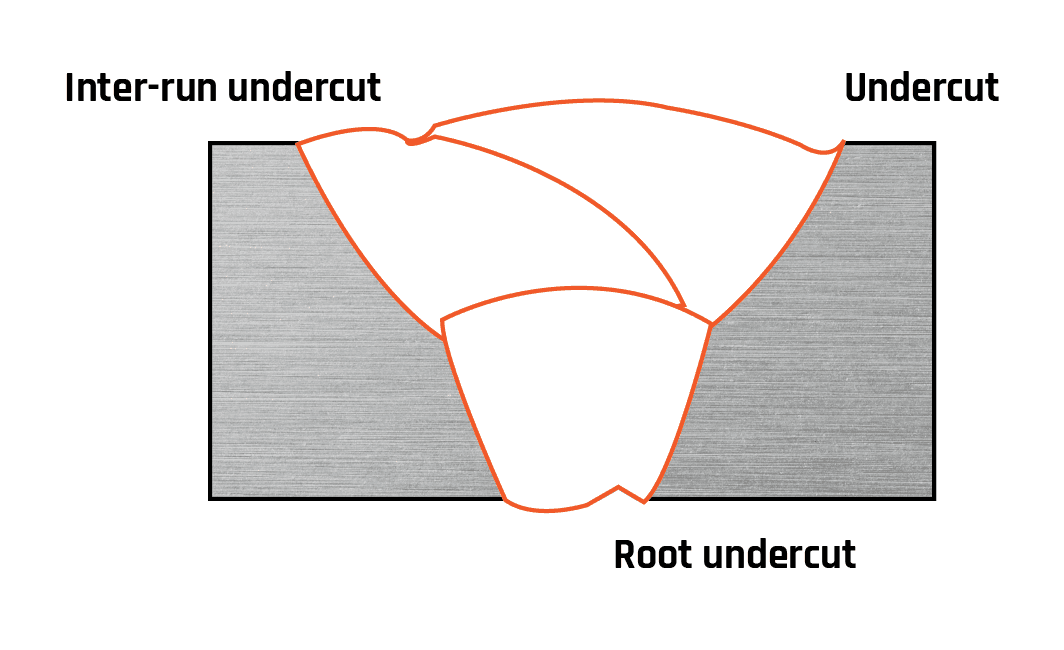

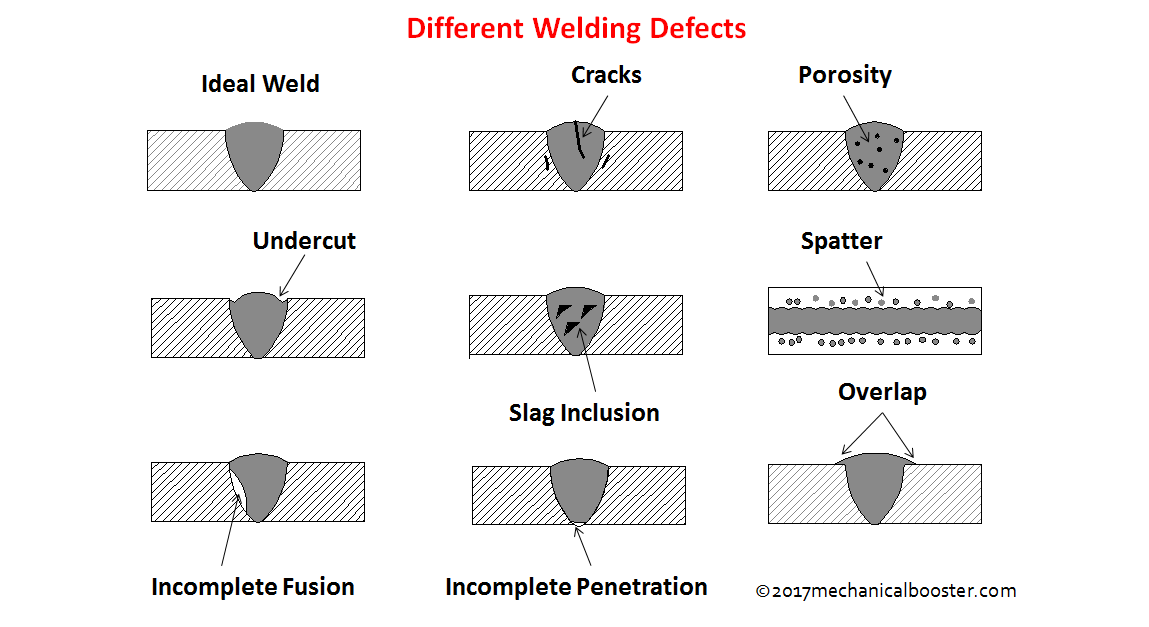

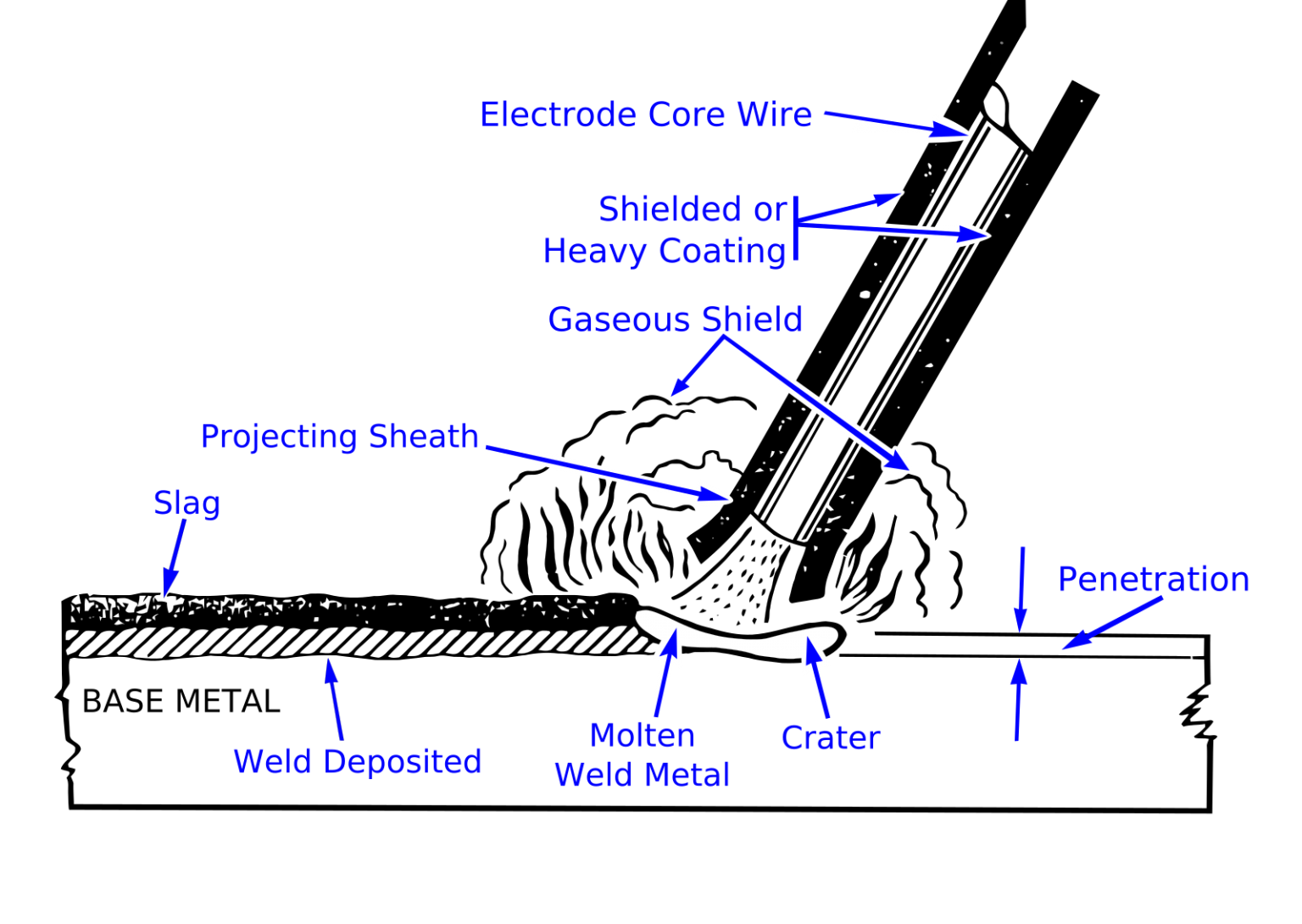

Undercut in MIG welding is caused by a combination of several factors, including the current, travel speed, and the type of wire being used. High current can cause the weld to penetrate too deeply, leading to an undercut. If the travel speed is too slow, the weld pool may become too large, resulting in an undercut.. An undercut is a groove melted into the base plate adjacent to the weld toe or weld root and left unfilled by weld metal. It weakens the joint, particularly when located in a highly stressed area, and can act as a crack initiation site. Undercut can be minimized or eliminated by proper techniques, electrode selection, and joint design.

What Is Undercut In Welding?

What Is Undercutting In Welding? (Causes and Prevention)

What is Undercut in Welding (Causes & Possible Remedies) WaterWelders

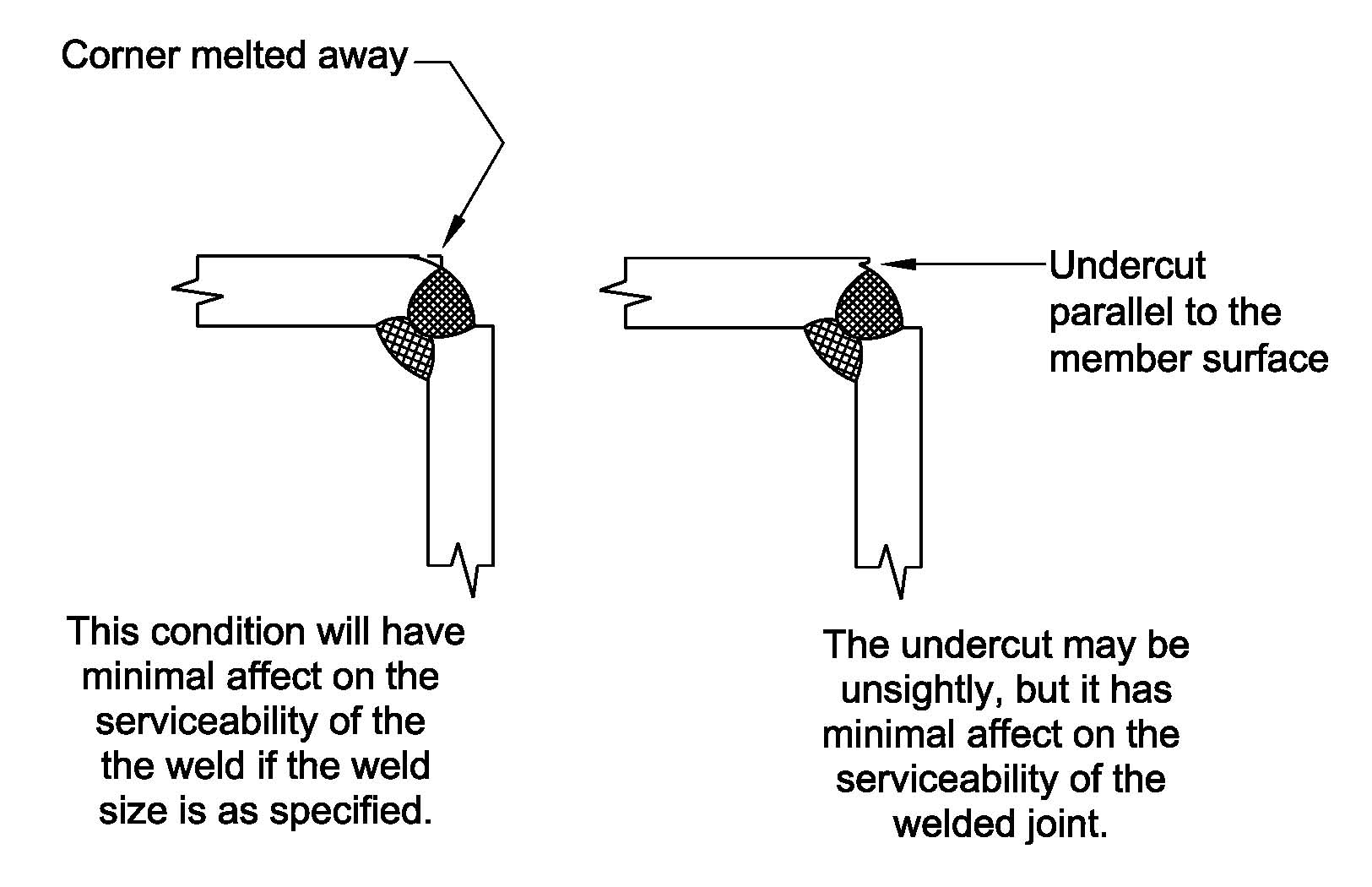

Fillet Weld Undercut

Welding Undercut Causes & Remedies Tips You Must Know Material Welding

What is Undercutting in Welding?

What is Undercut in Welding (Causes & Possible Remedies) WaterWelders

How do I get rid of/prevent undercut when TIG welding? r/Welding

How Do You Fix an Undercut Weld? Complete Guide Welders Lab

The Most Common Welding Defects Causes and Remedies

What Is Undercut In Welding 3 Best Tips & Helpful Guide

WQC Institute Of NDT What are the defects in welding?

What Is An Undercut In Welding?

What Is Undercut in Welding and How to Prevent It (Updated April 2023)

What is Undercut? How To Avoid Undercut Defect in Welding? YENA Engineering

Undercut in Welding What are the causes of and possible solutions?

What is Undercut in Welding (Causes & Possible Remedies) WaterWelders

How to Prevent Undercut in Stick Welding 12 Golden Tips

Welding Undercut What Is It? And How to Avoid It! Welders Manual

What is Undercutting in Welding? WelderStream

On this episode we tackle the problem of undercut and how to avoid it0:0:00 Intro0:2:48 welding0:8:07 results0:9:15 solutions to undercut0:10:27 Why undercut.. An undercut in welding is a type of weld defect that can occur when the weld reduces the cross-sectional thickness of the base metal. This can weaken the weld and cause it to fail. Undercuts can be caused by a variety of factors, including incorrect welding parameters, incorrect torch angle, or incorrect electrode size.